In the ever-evolving world of aerospace and defense manufacturing, precision is paramount. The materials chosen for components and parts must meet the highest standards of strength, durability, and weight efficiency. One such material that has soared to prominence in these industries is titanium. Renowned for its exceptional strength-to-weight ratio, corrosion resistance, and heat tolerance, titanium has become a go-to choice in CNC machine shops for aerospace and defense applications. In this article, we’ll delve into the world of titanium, exploring its pros and cons, and sharing insights that are invaluable to manufacturers in these critical sectors.

Titanium in Aerospace and Defense CNC Machine Shops

What is Titanium? Titanium, known for its chemical symbol Ti and atomic number 22, is a remarkable metallic element. It was first discovered in 1791 but wasn’t produced in its pure form until the early 20th century. Today, it is widely used in aerospace, defense, and numerous other industries due to its exceptional properties.

The Pros of Titanium in Aerospace and Defense CNC Machine Shops

1. Unrivaled Strength-to-Weight Ratio: One of the most compelling reasons for using titanium in aerospace and defense applications is its impressive strength-to-weight ratio. In fact, titanium is one of the strongest and lightest metallic materials available. This characteristic allows engineers to design components that are both robust and lightweight, vital for aircraft, missiles, and other defense systems.

2. Exceptional Corrosion Resistance: Titanium exhibits remarkable corrosion resistance, particularly against saltwater and various chemicals. This property makes it an ideal choice for components exposed to harsh environments, such as naval vessels and aircraft, which often encounter saltwater, extreme temperatures, and chemical agents.

3. Biocompatibility: Beyond aerospace and defense, titanium is renowned for its biocompatibility. This property has found applications in medical devices, including implants and prosthetics. Manufacturers in the aerospace and defense sectors, particularly those developing equipment for human use or astronautics, can leverage this property to ensure the well-being of operators.

4. High Heat Tolerance: Titanium has a high melting point, surpassing 3,000 degrees Fahrenheit (1,649 degrees Celsius). This makes it an ideal material for components subjected to high temperatures, such as aircraft engine parts and hypersonic missiles.

5. Low Thermal Expansion: In aerospace and defense applications, where temperature fluctuations are common, the low thermal expansion of titanium is an advantage. It helps maintain the integrity of components, even in extreme temperature environments.

6. Excellent Machinability: While titanium is known for its toughness, it is still machinable with the right equipment and techniques. Advances in CNC machining technology have made it increasingly feasible to work with titanium efficiently, enabling complex parts and structures to be manufactured accurately.

The Cons of Titanium in Aerospace and Defense CNC Machine Shops

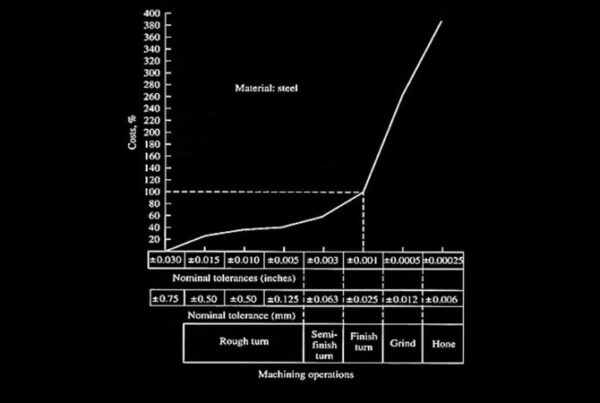

1. Costly Material: One of the most significant drawbacks of titanium is its high cost. It is more expensive than many other materials commonly used in aerospace and defense manufacturing. Manufacturers must carefully assess the cost-benefit ratio when considering titanium for a project.

2. Challenging Machining Process: Despite its excellent machinability, titanium presents machining challenges due to its toughness. It can wear out cutting tools more quickly than other materials, leading to higher machining costs. Additionally, titanium’s tendency to generate heat during machining requires careful tool selection and cutting fluid management.

3. Potential for Galling: Titanium is prone to galling, a phenomenon where metal surfaces adhere to each other during sliding contact. This can lead to increased friction and wear, impacting component longevity. Manufacturers must use lubricants and proper tooling to minimize galling.

4. Limited Supply Sources: The availability of high-quality titanium can be a concern. Manufacturers often rely on a limited number of suppliers, which can pose supply chain risks, especially during times of increased demand or geopolitical instability.

Other Interesting Insights for CNC Machining Titanium

1. Titanium Alloys: Titanium is often used in various alloy forms to enhance specific properties. Some common titanium alloys include Ti-6Al-4V (Grade 5) and Ti-6Al-4V ELI (Extra Low Interstitials). These alloys offer improved strength, heat resistance, and corrosion resistance compared to pure titanium.

2. Environmental Considerations: Titanium’s durability and longevity can contribute to sustainability in aerospace and defense applications. Components made from titanium can have a longer service life, reducing the need for frequent replacements and associated resource consumption.

3. Integration with Additive Manufacturing: The rise of additive manufacturing, commonly known as 3D printing, has opened up new possibilities for using titanium in aerospace and defense. This technology allows for the creation of complex, lightweight structures that were once challenging to manufacture with traditional methods.

In the aerospace and defense sectors, where precision, strength, and durability are non-negotiable, titanium stands as a material of choice. Its remarkable strength-to-weight ratio, corrosion resistance, heat tolerance, and biocompatibility offer numerous advantages. However, manufacturers must also contend with its high cost, machining challenges, and potential for galling.

Despite these challenges, the aerospace and defense industries continue to embrace titanium, driven by its unparalleled properties and the drive for innovation. As technology evolves and machining techniques improve, titanium is likely to play an even more significant role in shaping the future of aerospace and defense manufacturing, ensuring the reliability and performance of critical systems and equipment.

PS–Did you know that 85% of the manufactured SR-71 was made from titanium?