The aerospace and defense industries demand the highest standards of quality, precision, and reliability. Manufacturing components for these sectors requires adherence to rigorous standards and best practices to ensure the safety and performance of critical systems. In this article, we will explore some of the best practices in manufacturing aerospace and defense components that are essential for meeting these high standards.

Strict Adherence to Regulations and Standards

Manufacturing aerospace and defense components necessitates strict compliance with various regulations and standards. Organizations such as the Federal Aviation Administration (FAA) and the Department of Defense (DoD) impose stringent requirements. Staying up to date with these regulations is crucial. This often involves investing in training and quality management systems to ensure that every component meets or exceeds these standards.

Advanced Materials and Processes Selection

Choosing the right materials and manufacturing processes is critical. Aerospace and defense components must withstand extreme conditions, including high pressures, temperatures, and mechanical stresses. Advanced materials like titanium alloys, composites, and specialized coatings are often used. The selection of materials should be based on the specific requirements of each component.

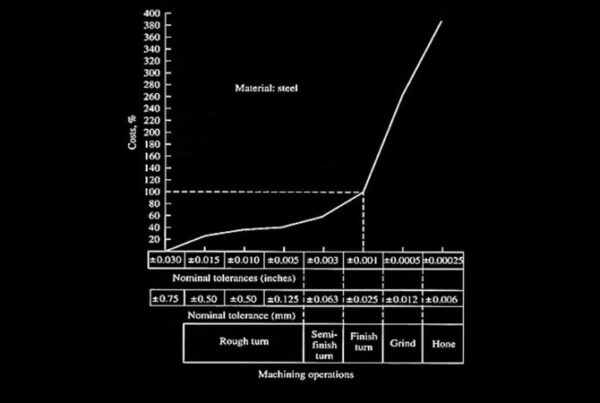

Precision Machining and Tolerances

Precision machining is at the heart of aerospace and defense component manufacturing. CNC (Computer Numerical Control) machining and other advanced machining technologies are used to achieve extremely tight tolerances and surface finishes. Quality control processes, such as CMM (Coordinate Measuring Machine) inspections, are essential to ensure the components meet specifications.

Design for Manufacturability (DFM)

Design for Manufacturability is a critical concept. Engineers and designers must work closely with manufacturing teams to optimize component designs for efficient production. This involves considering factors such as ease of machining, material availability, and minimizing complex geometries that can increase production time and costs.

Risk Management

Risk management is an integral part of aerospace and defense component manufacturing. Identifying potential risks, both in terms of design and production, and developing mitigation strategies is essential. This includes having contingency plans in place for unexpected issues that may arise during manufacturing.

Lean Manufacturing and Continuous Improvement

Implementing lean manufacturing principles and a culture of continuous improvement can significantly enhance efficiency and reduce waste. Techniques such as Six Sigma and Kaizen are commonly used to identify and eliminate defects and streamline production processes.

Supplier Quality Management

Aerospace and defense manufacturers often rely on a network of suppliers for materials and components. Establishing stringent supplier quality management processes is crucial to maintain consistent quality throughout the supply chain. Regular audits, performance evaluations, and collaboration with suppliers are essential components of this practice.

Quality Assurance and Testing

Rigorous quality assurance and testing procedures are vital in aerospace and defense manufacturing. Components often undergo extensive testing, including non-destructive testing (NDT) methods like X-ray and ultrasonic testing, to detect any defects or irregularities that could compromise safety or performance.

Documentation and Traceability

Comprehensive documentation and traceability are critical. Every step of the manufacturing process should be meticulously documented, allowing for full traceability of each component. This documentation provides transparency, aids in quality control, and is essential for certification and regulatory compliance.

Cybersecurity Measures

In an increasingly connected world, protecting sensitive data and systems from cyber threats is paramount. Aerospace and defense manufacturers must implement robust cybersecurity measures to safeguard intellectual property and sensitive information.

Manufacturing aerospace and defense components is a highly complex and demanding endeavor. Best practices in this industry are centered around precision, compliance, and continuous improvement. These practices ensure that components meet the highest standards of quality, safety, and reliability, ultimately contributing to the success and security of aerospace and defense systems. By adhering to these best practices, manufacturers can continue to innovate and deliver cutting-edge solutions for the most challenging and critical applications in the world.