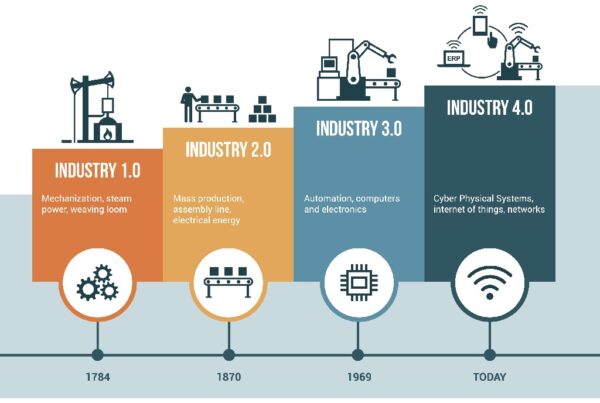

In the dynamic world of manufacturing, the advent of automation, especially in CNC (Computer Numerical Control) machining, has been nothing short of revolutionary. This article delves into the myriad benefits of automation in manufacturing, with a particular focus on how it enhances quality and reduces costs, thereby reshaping the industry’s landscape.

The Dawn of a New Era: Enhanced Quality through Automation

Quality is the cornerstone of manufacturing, and automation in CNC machining has elevated it to new heights. Here’s how:

- Precision and Consistency: Automation allows for unparalleled precision in manufacturing processes. CNC machines, governed by digital blueprints, can produce parts with extremely tight tolerances. This level of accuracy is consistently maintained across multiple production runs, eliminating human error and ensuring uniformity in quality.

- Complexity and Detail: Automated CNC machines excel at creating complex and intricate parts that would be difficult, if not impossible, to replicate manually. This capability opens doors to innovative designs and functionalities in products, enhancing their quality and appeal.

- Material Optimization: Automation also leads to more efficient use of materials. CNC machines can be programmed to optimize cutting paths and reduce waste, ensuring that every bit of material is used effectively.

- Reduced Risk of Defects: With less human intervention, the likelihood of defects decreases significantly. Automated systems can also be integrated with quality control measures that detect and rectify errors in real-time, further bolstering the quality of the final product.

Cost-Effectiveness: The Financial Upside of Automation

While the quality benefits are evident, the cost-saving aspects of automation in CNC machining are equally compelling:

- Labor Cost Reduction: One of the most immediate cost benefits of automation is the reduction in labor expenses. Automated machines can operate unattended or with minimal supervision, even outside regular working hours, thereby reducing the need for a large workforce.

- Increased Productivity: Automation leads to higher throughput. CNC machines can work at a consistent pace without breaks, enabling faster production times and higher volumes. This increase in productivity translates to a lower cost per unit, making the manufacturing process more economical.

- Reduced Downtime: Automated machines are less prone to errors that can cause downtime. Even maintenance can be scheduled and performed more efficiently, keeping the machines running optimally and avoiding costly production delays.

- Energy Efficiency: Modern automated machines are designed to be energy-efficient. They can optimize power use, reducing the overall energy costs associated with manufacturing.

- Material Savings: As mentioned earlier, the efficient use of materials not only enhances quality but also reduces costs. Less waste means more parts can be produced from the same amount of raw material.

Broader Benefits: Beyond Quality and Cost

The advantages of automation in CNC machining extend beyond quality and cost:

- Flexibility and Scalability: Automated systems can be quickly reprogrammed to adapt to new designs or changes in production volume, offering a level of flexibility that is invaluable in today’s fast-paced market. CNC machine shops can seamlessly scale up to bigger factories.

- Enhanced Worker Safety: Automation reduces the need for manual handling of heavy machinery or dangerous materials, thereby enhancing worker safety.

- Environmental Impact: With more efficient use of materials and energy, automation contributes to more sustainable manufacturing practices.

The integration of automation in CNC machining is a paradigm shift. It’s not just about keeping up with the competition; it’s about setting new standards in quality, driving down costs, and paving the way for innovative manufacturing practices. As technology continues to advance, the potential for further enhancements in automation is vast, promising an even more efficient, cost-effective, and high-quality future for the manufacturing industry.