In recent years, there has been a notable resurgence of manufacturing in the United States, particularly in the aerospace and defense industries. The “Made in America” tag has taken on new significance as companies seek to bolster domestic production for various reasons. This shift is not just about economic growth but also carries profound implications for America’s welfare, national security, and technological advancement. This blog post will explore the key challenges and solutions in machine shop manufacturing aerospace and defense components in the United States and highlight the benefits of embracing the “Made in America” approach.

The Importance of “Made in America” in Aerospace and Defense Machine Shop Manufacturing

- Strengthening National Security: A robust domestic manufacturing base is essential for safeguarding national security. Relying heavily on foreign sources for critical components can make the supply chain vulnerable to disruptions, geopolitical tensions, and trade uncertainties. By promoting “Made in America,” the nation can reduce its dependence on foreign suppliers, ensuring a secure and stable supply of aerospace and defense components.

- Job Creation and Economic Growth: Manufacturing plays a vital role in creating well-paying jobs and driving economic growth. A thriving aerospace and defense manufacturing sector translates into employment opportunities for skilled workers across the country. The income generated from these jobs further supports local businesses and stimulates the economy.

Challenges in Aerospace and Defense Machine Shop Components

- Technological Advancement and Innovation: To remain competitive in the global market, American manufacturers must continuously innovate and adopt cutting-edge technologies. However, the fast-paced nature of technological advancements poses a challenge to businesses that need to keep up with the latest trends to maintain a competitive edge.

- Skilled Labor Shortage: The resurgence of manufacturing in America demands a highly skilled workforce. Unfortunately, the country faces a shortage of skilled workers in the fields of engineering, machining, and precision manufacturing. Addressing this gap requires collaborative efforts from educational institutions, industries, and the government to invest in training and education programs.

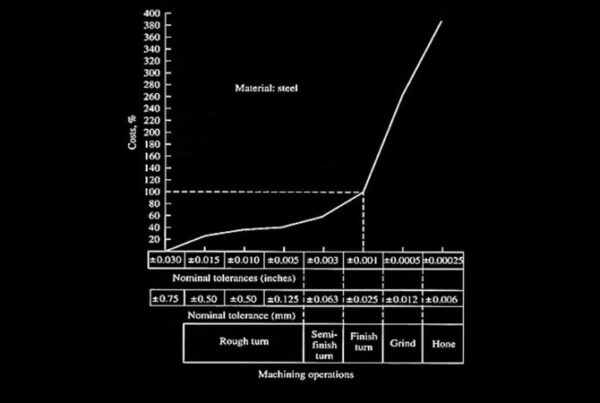

- Cost-Competitiveness: One of the significant challenges faced by domestic manufacturers is competing with lower-cost producers in foreign markets. Maintaining cost-competitiveness while adhering to stringent quality standards can be daunting for American companies.

- Supply Chain Complexity: The aerospace and defense industries often involve complex and interconnected supply chains. Managing the flow of raw materials, components, and finished products can be challenging, especially when dealing with global suppliers.

Solutions for Overcoming Challenges and Embracing “Made in America”

- Investment in Research and Development: To stay at the forefront of technology and innovation, American manufacturers should invest in research and development (R&D). Government incentives and grants can encourage companies to undertake R&D projects, fostering innovation and driving advancements in aerospace and defense component manufacturing.

- Collaboration between Industry and Academia: Bridging the skills gap requires collaboration between industry stakeholders and educational institutions. By aligning curricula with industry needs and offering apprenticeship programs, the workforce can be equipped with the necessary skills to thrive in the manufacturing sector.

- Automation and Advanced Manufacturing: Embracing automation and advanced manufacturing technologies can enhance productivity and cost-effectiveness. Automation can handle repetitive tasks, allowing skilled workers to focus on higher-value activities, while advanced manufacturing techniques like additive manufacturing offer new design possibilities and reduced material waste.

- Supporting Small and Medium-Sized Enterprises (SMEs): Small and medium-sized manufacturers play a vital role in the aerospace and defense supply chain. Offering financial incentives and technical support to SMEs can help them grow and contribute significantly to the “Made in America” movement.

- Strengthening Domestic Sourcing: Encouraging companies to source materials and components domestically can create a more resilient supply chain. Government policies and initiatives can incentivize domestic sourcing while ensuring that quality standards are met.

The resurgence of manufacturing in the aerospace and defense industries is a positive development for America’s welfare, national security, and economic growth. Embracing the “Made in America” approach provides numerous benefits, from reducing supply chain vulnerabilities to creating jobs and fostering innovation. However, to fully realize the potential of domestic manufacturing, challenges such as technological advancements, skilled labor shortages, and cost-competitiveness must be addressed through collaborative efforts between industry, academia, and the government. By doing so, the United States can continue to lead in aerospace and defense component manufacturing and secure a brighter and more prosperous future for the nation.