The Crucial Role of CNC Machining in the Aerospace and Defense Industry

In the dynamic and demanding fields of aerospace and defense, precision and reliability are of utmost importance. To meet these stringent requirements, the aerospace and defense industries rely heavily on advanced manufacturing processes. Among them, Computer Numerical Control (CNC) machining stands out as a pivotal technology that plays a vital role in the production of aerospace and defense components. This article explores the significance of CNC machining in these industries, highlighting its capabilities, advantages, and the impact it has on manufacturing processes.

CNC Machining in Aerospace & Defense

CNC machining is a manufacturing process that utilizes computerized controls to guide and automate machine tools. It involves the use of pre-programmed instructions to control the movements and actions of various cutting tools, enabling the creation of precise and complex components. CNC machines can operate with exceptional accuracy, repeatability, and efficiency, making them ideal for producing aerospace and defense parts.

Enhanced Precision and Accuracy

In the aerospace and defense sectors, precision and accuracy are paramount. CNC machining offers unparalleled levels of accuracy, enabling the production of intricate parts with tight tolerances. Components such as turbine blades, engine parts, landing gear, and airframe structures require precise dimensions and intricate geometries to ensure optimal performance and safety. CNC machines can achieve these specifications consistently, ensuring uniformity and adherence to design standards.

Versatility in Material Selection

Aerospace and defense applications often demand the use of diverse materials, including aluminum, titanium, stainless steel, composites, and high-performance alloys. CNC machining offers remarkable versatility in handling a wide range of materials, providing manufacturers the flexibility to work with the required materials for each application. This capability is particularly valuable in the aerospace and defense industries, where materials must possess exceptional strength-to-weight ratios and resistance to extreme temperatures, pressure, and corrosive environments.

Complex Component Manufacturing

The aerospace and defense industries frequently require intricate and complex components that cannot be easily produced through conventional machining methods. CNC machining allows for the creation of complex geometries and intricate features that meet the specific design requirements of aircraft and defense systems. From turbine blades with optimized airfoil profiles to lightweight structural components with intricate internal channels, CNC machines offer the capability to manufacture these highly specialized parts with efficiency and precision.

Streamlined CNC Production Processes

Efficiency is a crucial factor in aerospace and defense manufacturing. CNC machining optimizes production processes by reducing manual intervention, minimizing human errors, and increasing productivity. Once a CNC machine is programmed, it can operate continuously, executing the instructions with consistency and speed. This level of automation allows for uninterrupted manufacturing, faster turnaround times, and higher production volumes. Furthermore, CNC machines can be integrated into production lines, seamlessly coordinating with other automated systems, such as robotics and inspection equipment, to enhance overall efficiency and quality control.

Cost-Effective Manufacturing

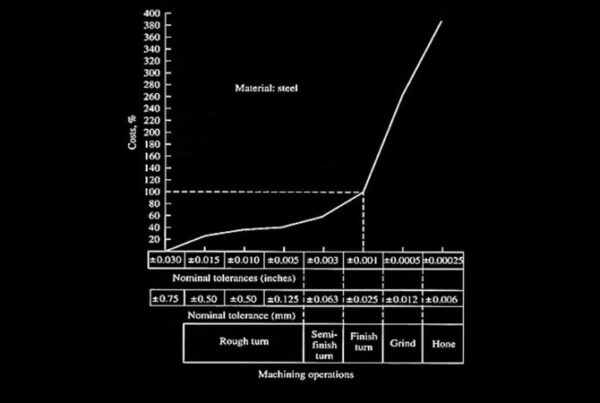

While CNC machining initially requires investment in equipment and programming, it offers long-term cost savings in the aerospace and defense industries. The precision and accuracy of CNC machines reduce material waste, as they can maximize the utilization of raw materials and minimize errors that could lead to costly rework or scrap. Additionally, the speed and efficiency of CNC machining increase productivity, resulting in shorter lead times and faster time-to-market. The overall reduction in production costs and increased operational efficiency contribute to the economic viability of aerospace and defense projects.

Quality Control and Traceability

Safety and quality control are paramount in the aerospace and defense sectors. CNC machining integrates seamlessly with computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, enabling real-time quality control throughout the production process. CNC machines can perform in-process measurements and inspections, ensuring adherence to design specifications and identifying any deviations promptly. Furthermore, CNC machining provides traceability by generating detailed records of production parameters and measurements, facilitating product validation, compliance, and auditing.

CNC machining has revolutionized the aerospace and defense industries by enabling the efficient and precise production of complex components. Its ability to provide exceptional precision, versatility in material selection, and streamlined production processes makes it an indispensable technology in these demanding sectors. As aerospace and defense systems continue to advance and evolve, CNC machining will play an increasingly vital role in meeting the ever-growing demands for safety, performance, and reliability.