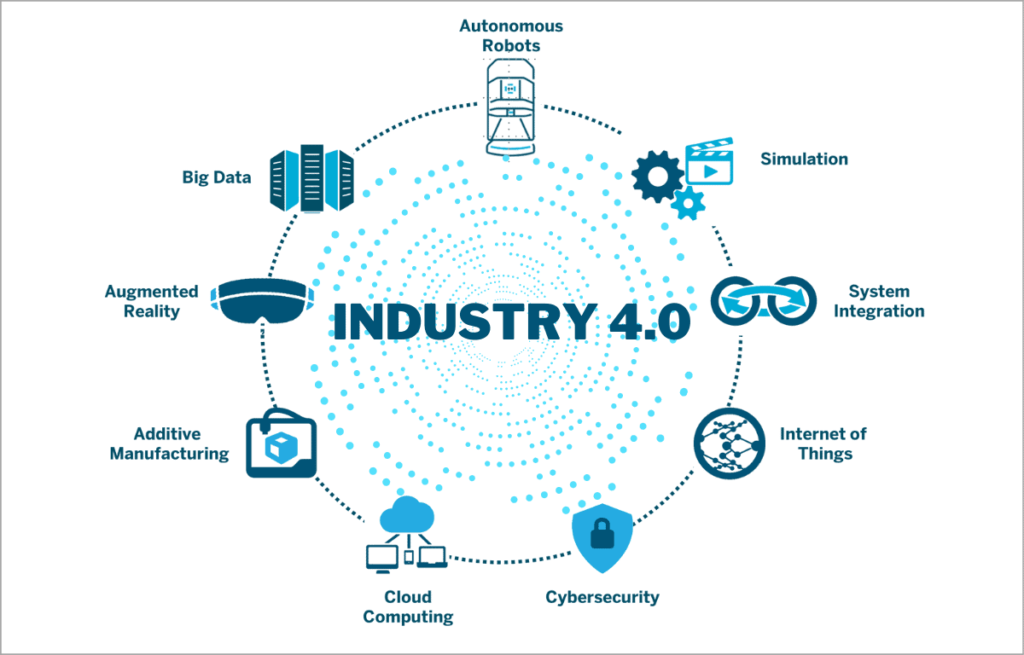

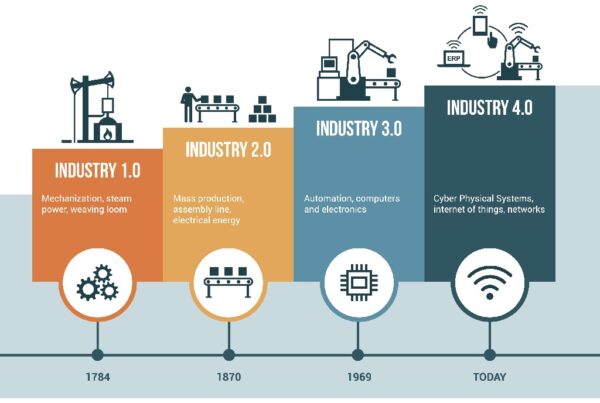

Industry 4.0, also known as the Fourth Industrial Revolution, is transforming the manufacturing industry with the integration of advanced technologies such as automation, artificial intelligence (AI), the Internet of Things (IoT), and cloud computing. These technologies are allowing manufacturers to streamline their operations, reduce costs, and improve productivity. In this article, we will discuss some of the most important Industry 4.0 technologies for the manufacturing industry.

Automation and Robotics

Automation and robotics are critical components of Industry 4.0, providing manufacturers with the ability to automate repetitive and time-consuming tasks. Robots can perform a wide range of tasks, from assembling products to packing and shipping. They can also work alongside human workers, improving safety and efficiency.

Advances in automation and robotics are allowing manufacturers to achieve greater precision, accuracy, and speed in their operations. Robotics can also be integrated with other Industry 4.0 technologies, such as AI and IoT, to enable more intelligent and efficient manufacturing processes.

Artificial Intelligence

AI is another key technology in Industry 4.0, providing manufacturers with the ability to analyze vast amounts of data and make more informed decisions. AI-powered systems can detect patterns and anomalies in data, identify potential quality issues, and optimize production processes.

Machine learning, a subset of AI, is particularly valuable for manufacturers, as it can learn from data to improve processes and make predictions. For example, a machine learning system can analyze data from sensors to predict when a machine is likely to fail, allowing manufacturers to perform maintenance before a breakdown occurs.

Internet of Things

The Internet of Things (IoT) refers to the network of devices, sensors, and machines that are connected to the internet and can communicate with each other. In the manufacturing industry, IoT is being used to monitor machines and processes, collect data, and optimize operations.

For example, sensors can be installed on machines to monitor their performance and detect potential issues before they lead to downtime. IoT data can also be used to optimize production schedules and inventory management.

Cloud Computing

Cloud computing is another important technology in Industry 4.0, providing manufacturers with the ability to store and analyze data on remote servers. This allows manufacturers to access their data from anywhere, collaborate with partners, and scale their operations as needed.

Cloud computing is particularly valuable for manufacturers that operate in multiple locations, as it enables them to centralize their data and standardize their operations. It also allows manufacturers to take advantage of advanced analytics and machine learning algorithms that require large amounts of computing power.

Additive Manufacturing

Additive manufacturing, also known as 3D printing, is a rapidly evolving technology that is transforming the manufacturing industry. With 3D printing, manufacturers can produce complex and customized products without the need for specialized tooling.

Additive manufacturing is particularly valuable for producing low-volume, high-value parts, such as those used in aerospace and medical industries. It also enables manufacturers to rapidly prototype new products and iterate on designs.

Augmented Reality

Augmented reality (AR) is a technology that overlays digital information onto the real world. In the manufacturing industry, AR is being used to provide workers with real-time information and instructions, improving efficiency and reducing errors.

AR can be used to provide workers with step-by-step instructions for assembling products or performing maintenance tasks. It can also be used to provide workers with real-time data on machine performance or inventory levels.

Conclusion

Industry 4.0 technologies are transforming the manufacturing industry, enabling manufacturers to achieve greater efficiency, productivity, and profitability. Automation and robotics, artificial intelligence, the Internet of Things, cloud computing, additive manufacturing, and augmented reality are all critical components of Industry 4.0, and are helping manufacturers to stay competitive in an increasingly complex and demanding market.