CNC machining and 3D printing are two manufacturing processes that have become increasingly popular in recent years. While both processes have their advantages, there are several key advantages to CNC machining over 3D printing. In this article, we will explore these advantages and discuss why CNC machining is often the preferred manufacturing process in certain industries.

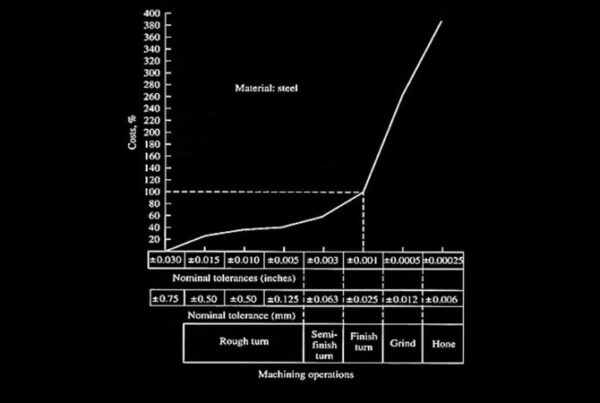

Precision and Accuracy

One of the primary advantages of CNC machining over 3D printing is the precision and accuracy that can be achieved. CNC machines are capable of producing parts with very tight tolerances, which is important in industries such as aerospace, medical, and automotive where precision is critical. In contrast, 3D printing is often limited in terms of the level of precision that can be achieved, particularly with smaller parts.

Material Selection

Another advantage of CNC machining is the ability to work with a wide range of materials, including metals, plastics, and composites. CNC machines can be used to produce parts from a variety of materials, which makes them suitable for use in a wide range of industries. In contrast, 3D printing is often limited to a narrower range of materials, and the quality of the finished product can be affected by the type of material used.

Strength and Durability

CNC machined parts are often stronger and more durable than 3D printed parts. CNC machines can produce parts with a higher density and more consistent structure, which makes them better suited for use in applications where strength and durability are important. 3D printed parts can be more brittle and have a lower strength to weight ratio, which can limit their usefulness in certain industries.

Surface Finish

CNC machining can produce parts with a much smoother surface finish than 3D printing. CNC machines can produce parts with a very high level of detail and smoothness, which makes them ideal for use in applications where aesthetics are important. 3D printing can produce parts with a rougher surface finish, which may require additional post-processing to achieve the desired level of smoothness.

Scalability

CNC machining is often more scalable than 3D printing. CNC machines can produce parts at a much faster rate than 3D printers, which makes them better suited for use in industries where large quantities of parts are required. Additionally, CNC machines can be used to produce parts in a variety of sizes and shapes, which makes them more versatile than 3D printers.

Cost

While the initial cost of purchasing a CNC machine can be higher than that of a 3D printer, CNC machining can often be more cost-effective in the long run. CNC machines can produce parts at a faster rate and with greater precision, which can result in a lower cost per part. Additionally, CNC machines can be used to produce parts from a wider range of materials, which can help to reduce material costs over time.

Conclusion

While both CNC machining and 3D printing have their advantages, there are several key advantages to CNC machining that make it the preferred manufacturing process in certain industries. CNC machining can produce parts with a higher level of precision, a wider range of materials, greater strength and durability, a smoother surface finish, and at a faster rate than 3D printing. Additionally, CNC machining can be more cost-effective in the long run, particularly in industries where large quantities of parts are required. For these reasons, CNC machining remains a critical manufacturing process in many industries.