Machine shops are bustling hubs of innovation and productivity, serving as the backbone of numerous industries in Los Angeles. These dynamic manufacturers are responsible for the creation, modification, and repair of intricate machinery and components. Amidst the constant hum of machinery and the relentless pursuit of precision, it is crucial to prioritize safety to protect the lives and well-being of workers. This article explores the importance of safety in a machine shop in Los Angeles, California, highlighting the benefits of a robust safety culture and the measures that can be implemented to ensure a secure working environment.

The primary reason safety takes precedence in a machine shop is it can be extremely dangerous. The preservation of human life is paramount. The inherent risks associated with powerful machinery, sharp tools, and heavy equipment demand stringent safety measures. By implementing comprehensive safety protocols, such as providing appropriate personal protective equipment (PPE), conducting regular safety training, and adhering to industry standards, machine shops can significantly reduce the likelihood of accidents, injuries, and even fatalities.

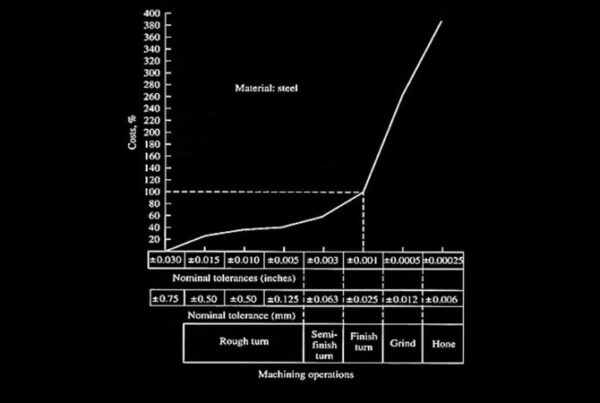

The safe machine shop is also able to contain its costs, passing savings onto customers. A machine shop accident can result in severe financial ramifications for both the workers and the organization. Workplace injuries lead to medical expenses, workers’ compensation claims, and potential legal liabilities. The direct and indirect costs associated with accidents, including loss of productivity, damaged equipment, and increased insurance premiums, can have a detrimental impact on the profitability of the shop. By prioritizing safety, machine shops can mitigate these risks and lower costs for their customers.

Safety and productivity go hand in hand. A safe working environment boosts employee morale, leading to higher levels of engagement and job satisfaction. When workers feel secure and protected, they can focus on their tasks without the constant worry of accidents or injuries. This sense of security fosters a culture of trust and teamwork, promoting effective communication and collaboration within the machine shop. Additionally, by implementing safety protocols, such as regular maintenance schedules and equipment inspections, machine shops can prevent unexpected breakdowns and reduce downtime, thus optimizing productivity.

Machine shops in Los Angeles, like any other workplace, must adhere to local, state, and federal regulations regarding workplace safety. These regulations, such as the Occupational Safety and Health Administration (OSHA) standards, are designed to ensure the well-being of workers and prevent hazardous incidents. Non-compliance can result in penalties, fines, and even legal consequences. By prioritizing safety and ensuring compliance with all relevant regulations, machine shops in Los Angeles can demonstrate their commitment to responsible business practices.

A machine shop that prioritizes safety creates a positive work culture that values the well-being of its employees. By investing in safety training programs, providing ongoing safety education, and encouraging workers to actively participate in safety initiatives, machine shops can foster a sense of ownership and responsibility among their employees. In turn, this positive work culture can attract skilled workers, enhance retention rates, and create a reputation as a safe and reliable employer.

An effective safety program in a machine shop involves the identification and management of potential risks. By conducting comprehensive risk assessments, shops can identify hazardous processes, potential points of failure, and areas of risk.

Avalon CNC prides itself on keeping its workers and customers safe from harm, and strives tirelessly to maintain a healthy, safe, and fun working environment.